SAFe as a flow-based system is not new … but

Flow has always been central in the framework as SAFe is described as a flow-based system, and flow is integrated in the Lean-Agile Mindset and into the way we work. SAFe describes Lean enterprises as striving to achieve a continuous, sustainable flow of value, adding Lean thinking to the enterprise focus on stop starting, start finishing, and identifying and removing delays and waste (non-value-added activities). In addition, the principles of flow, including understanding the full Development Value Stream, visualizing, and limiting Work in Process (WIP), and reducing batch sizes and managing queue lengths, are described as key to success to establish a continuous flow.

And even though flow seems easily enough to understand in theory, when reality hits, flow is one of the hardest things for an enterprise to achieve. In previous versions of SAFe, flow has been omnipresent behind the scenes, the problem has been that if you are not already aware of it, it’s been hard to understand that it’s there and what it really is.

When working with organizations adopting SAFe and its values, principles, and practices, what I see is that Kanban boards are being used to visualize the flow of value, but they are primarily (only) being used for visualization. As seeing is the first thing needed – You cannot manage what you cannot see! – this is a natural first step. But in order to manage the flow, reflection and action on what you see is the next step, but the policies needed identify and act on problems in the flow are often not in place, nor even considered. Enterprises adopting SAFe seems to be unaware of the importace of managing flow and, a lot of times, unable to see that SAFe is a Flow System introducing one connected Kanban System.

The new version of the framework takes an important step in the right direction to help with this and opens up for a whole new understanding of Flow.

Accelerating Value Flow

The updates and additions to SAFe 6.0 not only highlights that SAFe is a flow-based system, it integrates the three extended guidance articles introduced in 2022 on Accelerating Flow – Accelerating Flow with SAFe, Value Stream Management in SAFe, and Make Value Flow Without Interruptions, including what was first The 8 Flow Accelerators, into the framework.

For a summary of Accelerating the Flow of Customer Value: The 8 Flow Accelerators, check out this recording from when SAFe Fellow Andrew Sales from Scaled Agile, Inc. visited one of our RTE Meetups on ART Flow in September.

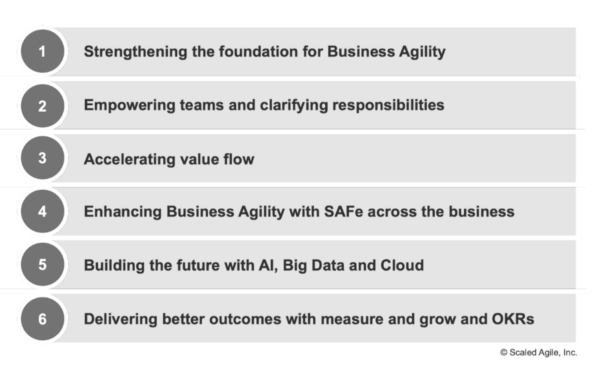

Now, Accelerating Value Flow is one of the new six primary themes of SAFe 6.0, and flow is also integrated into at least two of the other primary themes through the introduction of Business Agility Value Stream (BAVS), the Lean-Agile Mindset, and the respective roles’ responsibility for understanding and optimizing flow.

To furthermore put emphasis on SAFe as a flow-based system and on the importance of governing the flow, SAFe 6.0 adds a collection of six articles describing flow and how to optimize it;

- Value Stream Management,

- Principle #6- Make value flow without interruptions,

- Team Flow,

- ART Flow,

- Solution Train Flow, and

- Portfolio Flow.

These articles together with the Extended SAFe Guidance article Applying Kanban in SAFe help deepening the understanding of what a Kanban system is and what it takes to achieve an end-to-end flow.

Value Stream Management

The principles of Lean Thinking, derived from Lean Manufacturing and applied to product development, were previously only shortly described as part of the Lean-Agile Mindset and the SAFe House of Lean and summarized as:

- Precisely specify value by product

- Identify the value stream for each product

- Make value flow without interruptions

- Let the customer pull value from the producer

- Pursue perfection

The Value Stream Management article adds clarification and details to the five principles above, and to the importance of Lean Thinking as a shared mindset. By calling them out as principles and putting extended focus on them, Lean Thinking is not only better understood but there is also a greater emphasis on its importance as one of the core building blocks of SAFe. I like how the article deep dives into how the five principles enables the end-to-end flow and how they Lean connects to different other aspects of the framework.

One of the things I really like, is that attention is put on the importance of metrics. Again, not just stating that it is important, but pointing to how. And another great thing about digging deeper into the principles is that the importance of pull as opposed to push to enable flow is called out, and further guidance on how to make this happen is provided in Principle 6 – Make value flow without interruptions, which highlights the 8 Flow Accelerators, or as they are presented in this new version of the framework, the eight properties of a system of value flow. And, additional guidance is found in the articles describing flow from a Team, ART, Solution Train and Portfolio perspective.

Principle 6 – Make Value Flow without Interruptions

The most noticeable change might be the total makeover of SAFe principle #6, the principle previously known as Visualize and limit WIP, reduce batch sizes, and manage queue lengths, a long and cumbersome name, and a limited take on what makes flow work.

By moving much of the content of one of the pillars of the SAFe House of Lean into the principle, there is a new and more comprehensive meaning to the principle. Because even if visualizing and limit WIP, reducing batch sizes, and managing queue lengths are very important parts of achieving flow, they’re not all, and they’re definitely not enough.

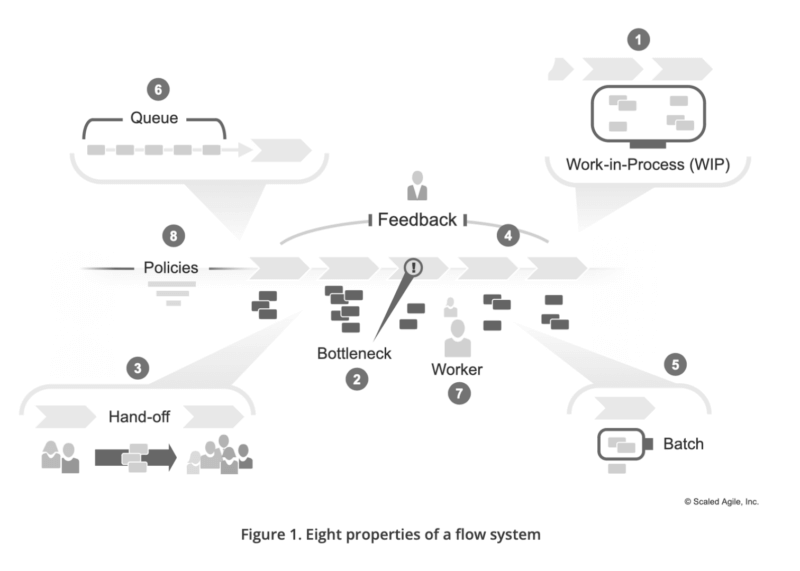

In its new and improved version, SAFe Principle 6 aims to describe how to make value flow without interruptions and eight properties of a flow system are introduced, and for each property, there are suggested actions, or flow accelerators, that help optimize flow at any level.

SAFe describes the properties in the above picture briefly as follows:

- Work in process. There is always some work in process in the system; if there weren’t, there could be no flow of value.

- Bottlenecks. In every flow system, one or more bottlenecks effectively limit the flow through the entire system.

- Handoffs. Handoffs wouldn’t be necessary if one person could do all the work. But in any material flow system, different individuals and teams will have different skills and responsibilities. Each plays its part in moving a work item through the system.

- Feedback. Customer and stakeholder feedback is integral to efficient and effective outcomes. Ideally, feedback happens throughout the entire process.

- Batch. As any system has a finite capacity, all the work can’t be done at once. Therefore, work through the system occurs in batches designed to be as efficient as possible.

- Queue. It all starts with a set of work items to be done. In addition, each value stream needs a prioritizing mechanism to sequence the work for the best value.

- Worker. People do the critical work of moving work items from one state to another.

- Policies. Policies are integral to flow. They may be local policies — like team-based policies that determine how a work item moves from step to step— or global policies like those that govern how work is performed within the company.

The addition of the eight properties and the flow accelerators, as well as a higher attention to what a Kanban system is and how to apply Kanban in SAFe, gives enterprises a better foundation for understanding, working with and optimizing flow. If we go deeper into the workings of flow, and how to work with constraints to improve it, there is more to it than the eight accelerators, but, the SAFe 6.0 updates include important aspects previously hidden away or not even covered by the framework, and that’s a very good start.

The way flow is now described and emphasized in the framework also makes it easier to understand that what SAFe introduces is one connected Kanban system.

Kanban

The Extended SAFe Guidance article Applying Kanban in SAFe provides an overview of Kanban, how to establish a Kanban system, and describes SAFe’s connected Kanban system. There are also some updates made in the framework in regard to the backlogs and previous articles to emphasize that we are dealing with one common Kanban system. The most important being the way SAFe 6.0 rewrites it’s take on flow through the six articles describing flow, how it’s connected and how to optimize it, but changes also include updates to the visualizations in the Big Picture, removing the vertical Kanban label from all backlog icons and, changing the Backlog state in all Kanban systems to Ready.

Kanban has been present in SAFe in terms of a lean workflow management method for visualizing and understanding workflow, optimize efficiency, and improve relentlessly. Like I pointed out earlier in the blog, even if Kanban has been a part of SAFe, it seems to mainly be used for visualization out there. The new version of the framework and extended guidance on how to actually use it offers a whole new toolbox for enterprises to work with when understanding and optimizing end-to-end flow.

The roots of Kanban are found in Lean Manufacturing, just as roots of the principles of Lean Thinking, and I believe that the work of David J. Anderson (Anderson, David J. Kanban: Successful Evolutionary Change for Your Technology Business. Sequim, Washington: Blue Hole Press, 2010), complements the work of Ward (Ward, Allen, and Durward Sobeck. Lean Product and Process Development. Lean Enterprise Institute, 2014), Reinertsen (Reinertsen, Donald G. The Principles of Product Development Flow: Second Generation Lean Product Development. Celeritas, 2009), and Poppendieck (Poppendieck, Mary, and Tom Poppendieck. Implementing Lean Software Development: From Concept to Cash. Addison-Wesley, 2006) referred to in the Value Stream Management and Principle #6 articles.

In his foreword of Anderson’s book mentioned above, Reinertsen describes how he encourages Anderson to look beyond the bottleneck focus of Eli Goldratt’s Theory of Constraints (TOC) and explains to him that “the dramatic success of the Toyota Production System (TPS) had nothing to do with finding and eliminating bottlenecks. Toyota’s performance gains came from using batch-size reduction and variability reduction to reduce work-in-process inventory. It was the reduction in inventory that unlocked the economic benefits, and it was WIP-constraining systems like kanban that made this possible. (…).

He goes on to say “The way kanban boards make WIP visible is striking, but it is only one small aspect of this approach. (…) The real insights lie in aspects like the design of arrival and departure processes, the management of non-fungible resources, and the use of classes of service.”

There is still much more to learn from Kanban when it comes to managing flow, and a lot more on how to work with learning to create new abilities in enterprises adopting SAFe, but having said that, I am delighted that the new version of the framework is a Flow Release highlighting that SAFe is a flow-based system, and by incorporating a deeper understanding of principles of Lean Thinking through Value Stream Management and a more comprehensive understanding of the concepts of a flow system we are starting to connect the dots when it comes to achieving a continuous and sustainable end-to-end value flow.

For a summary and analysis of the SAFe version 6.0 update, I recommend reading Carl Starendals latest We Are Movement blog post What is new in SAFe 6.0.